The textile and apparel industry is one of the largest manufacturing sectors in Bangladesh and a major contributor to the country’s economy. It accounts for over 80% of Bangladesh’s total export earnings and employs around 4.5 million people, mostly women. The industry has grown rapidly in recent years due to low labor costs, a large workforce, and favorable government policies. Bangladesh is the world’s second-largest garment exporter after China, with major customers in Europe and North America.

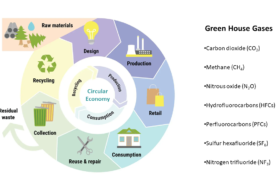

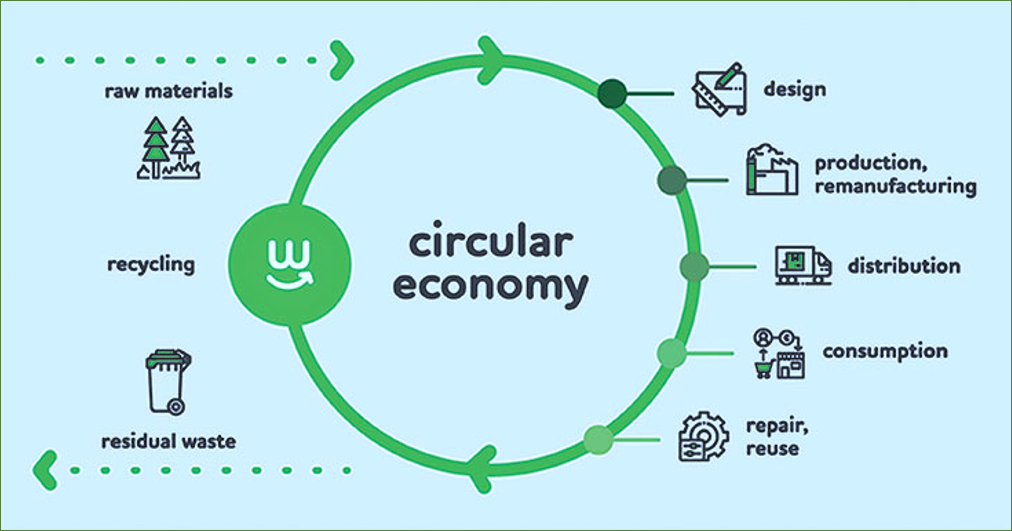

However, the linear production and consumption model of the industry has resulted in significant environmental degradation and resource depletion. To address these issues, the concept of the circular economy has gained traction in the industry. The adoption of circular economy practices in Bangladesh’s apparel industry is still at an early stage. While some companies have taken steps to implement circular practices, the overall adoption rate remains low. One of the main challenges is the lack of awareness and understanding of circular economy principles among industry stakeholders, including manufacturers, suppliers, and consumers. There is a need for education and training programs to build knowledge and capacity and facilitate the adoption of circular practices. Another challenge is the lack of infrastructure and technologies to support circular practices. Bangladesh has limited waste management infrastructure and recycling facilities, making it difficult to implement circular practices on a large scale. There is a need for investment in infrastructure and technologies to enable the transition to a circular economy. Despite these challenges, there are some positive developments in the industry. Several companies have introduced recycling and upcycling initiatives to reduce waste and promote circularity. For example, the Bangladesh Garment Manufacturers and Exporters Association (BGMEA) has established a pilot project to recycle textile waste into new products.

According to a report by the Bangladesh Garment Manufacturers and Exporters Association (BGMEA), circular economy practices have the potential to reduce textile waste by up to 70%. This would not only have environmental benefits but also economic benefits, as it would reduce the costs of waste disposal and raw material procurement. Another report by the International Finance Corporation (IFC) and the Boston Consulting Group (BCG) projects that the circular economy could generate up to $2.4 billion in value for Bangladesh’s textile and apparel industry by 2030. This would be achieved through the reduction of waste and the creation of new revenue streams from recycled and upcycled materials. Bangladesh government’s inclusion of circular economy principles in its 8th Five-Year Plan signals a commitment to promoting sustainable production and consumption patterns in the country. The plan includes targets to increase resource efficiency, reduce waste, and promote sustainable practices across various sectors, including the textile and apparel industry.

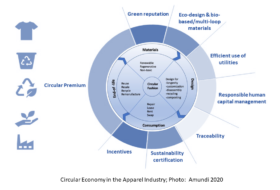

However, the adoption of circular economy principles in Bangladesh’s apparel industry could help to enhance its position in the global value chain by improving efficiency, competitiveness, and access to new revenue streams. This can create new opportunities for the industry and help it to contribute to the global market in a more sustainable way. According to a report by the Ellen MacArthur Foundation, a circular economy in the textile industry could generate over $500 billion in value globally by 2030, while reducing greenhouse gas emissions by 50%. This highlights the potential economic and environmental benefits of circular economy practices in the industry.

In terms of improved brand image and market access, a survey by Nielsen found that 66% of consumers are willing to pay more for sustainable and environmentally friendly products. Another study by Cone Communications found that 87% of consumers will purchase a product because a company advocated for an issue they cared about, such as environmental sustainability. Several global brands have already recognized the benefits of circular economy practices and are incorporating them into their supply chains. For example, in 2017, H&M launched its “Close the Loop” collection, made entirely of recycled materials. In 2019, Zara announced its commitment to using 100% sustainable fabrics by 2025.

In Bangladesh, some companies are already implementing circular practices. For example, the company DBL Group has implemented a closed-loop production process, where water is recycled and reused in its textile mills. Another company, Viyellatex, has a recycling unit that produces new yarn from textile waste. Bangladesh’s government has recognized the importance of sustainable practices in the industry and has set targets for reducing water and energy use in textile factories. In 2019, the Bangladesh Garment Manufacturers and Exporters Association (BGMEA) launched a sustainability initiative, aiming to make the country’s apparel industry more sustainable by promoting the use of renewable energy, reducing waste, and improving water and energy efficiency. There has been a growing trend towards sustainable and circular practices in the global apparel industry, and Bangladesh’s apparel industry has the potential to tap into this trend and contribute to the global value chain in a more sustainable way.

Based on current trends and initiatives in the Bangladesh apparel industry, it is likely that circular economy practices will continue to gain traction and contribute to the industry’s sustainability goals. Here are some propositions, assumptions and divination regarding the circular economy principles in Bangladesh’s apparel industry and its position in the global value chain;

- Increased adoption of circular practices: With the support of the government and industry associations, more apparel manufacturers in Bangladesh are likely to adopt circular economy practices in their production processes. According to a report by the Bangladesh Garment Manufacturers and Exporters Association (BGMEA), more than 70% of the country’s garment factories have already implemented some form of eco-friendly production practices.

- Reduced environmental impact: Circular practices such as water recycling, waste reduction, and use of renewable energy sources can significantly reduce the environmental impact of the apparel industry. According to a study by the International Finance Corporation (IFC), water consumption in Bangladesh’s textile industry can be reduced by up to 70% through the adoption of circular practices.

- Increased market access: With growing consumer awareness and demand for sustainable products, apparel manufacturers in Bangladesh that adopt circular practices are likely to have improved market access and greater opportunities for exporting to countries with stricter environmental regulations. According to the Export Promotion Bureau of Bangladesh, the country’s exports of eco-friendly apparel increased by 12.5% in 2020 compared to the previous year.

- Economic benefits: Circular practices in the apparel industry can lead to cost savings through reduced material and energy consumption, as well as increased efficiency in production processes. According to a report by the Ellen MacArthur Foundation, circular practices in the global textile industry could generate $500 billion in value by 2030.

- Job creation: As circular practices become more prevalent in the Bangladesh apparel industry, there is potential for job creation in areas such as waste management, recycling, and renewable energy production. This could contribute to the country’s economic development and social welfare.

- Improved resource efficiency: The adoption of circular practices in the apparel industry can lead to improved resource efficiency by reducing waste generation and maximizing the use of existing resources. This can lead to reduced raw material costs and increased profitability for apparel manufacturers. According to a report by the Ellen MacArthur Foundation, by 2030, the adoption of circular economy practices in the textile industry could reduce the demand for virgin materials by 39%.

- Reduced carbon emissions: The apparel industry is a significant contributor to greenhouse gas emissions, primarily due to energy consumption and transportation. The adoption of circular practices, such as the use of renewable energy sources and improved supply chain management, can lead to significant reductions in carbon emissions. According to a report by the IFC, the adoption of circular economy practices in the textile industry could lead to a 31% reduction in carbon emissions by 2030.

- Reduced environmental pollution: The apparel industry is notorious for polluting water sources and contributing to environmental degradation. The adoption of circular practices such as water recycling, waste reduction, and better chemical management can significantly reduce the environmental pollution caused by the industry. According to a report by the World Bank, the textile industry in Bangladesh is the second-largest polluter of the country’s waterways.

- Strengthened resilience: The adoption of circular practices in the apparel industry can lead to greater resilience in the face of environmental and economic shocks. By reducing dependence on virgin resources, improving resource efficiency, and creating closed-loop systems, apparel manufacturers can reduce their exposure to supply chain disruptions and price volatility.

- Improved reputation: The adoption of circular practices in the apparel industry can improve the reputation of apparel manufacturers and their brands. By demonstrating a commitment to sustainability and social responsibility, apparel manufacturers can build trust and loyalty with customers, suppliers, and other stakeholders. According to a survey by McKinsey & Company, 67% of consumers are willing to pay a premium for sustainable products.

- Improved working conditions: The adoption of circular practices can lead to improved working conditions for apparel industry workers. By reducing the demand for virgin materials, the industry can reduce the pressure on workers to meet production targets, leading to better working conditions and reduced risks of labor exploitation.

- Increased competitiveness: The adoption of circular practices in the apparel industry can increase competitiveness by reducing costs, improving resource efficiency, and enhancing brand reputation. According to a report by the McKinsey Center for Business and Environment, companies that adopt circular economy practices can increase their profitability by up to 4.5%.

- Reduced waste management costs: The adoption of circular practices in the apparel industry can lead to significant reductions in waste management costs. By reducing the amount of waste generated and maximizing the use of existing resources, apparel manufacturers can reduce their waste disposal and recycling costs.

- Improved access to raw materials: The adoption of circular practices can improve access to raw materials by reducing the dependence on virgin resources. This can help to secure the supply chain and reduce the risks of price volatility and supply chain disruptions.

In conclusion, the adoption of circular economy practices in Bangladesh’s apparel industry has the potential to bring significant benefits across environmental, social, and economic dimensions. With the right policies, incentives, and investments, the industry can transition toward a more sustainable and resilient future the industry has the potential to tap into ongoing trends and contribute to the global value chain in a more sustainable way.

Author:

Dr. Md Ekram Hossain

Research Faculty (Assistant Professor), Hohai University, China

Email: mdekram_hossain@hhu.edu.cn