The apparel industry in Bangladesh is one of the largest and most important sectors of the country’s economy, providing employment to millions of people and accounting for a significant share of the country’s GDP. However, the industry is also associated with a number of environmental and social challenges, including waste generation, water pollution, and poor working conditions.

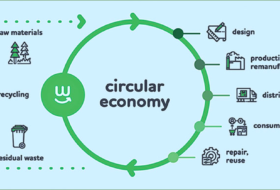

Circular economy principles can offer a way forward for the apparel industry in Bangladesh to address these challenges while also promoting economic growth and social development. A circular economy is an economic system that is restorative and regenerative by design, aiming to keep products, components, and materials at their highest value and utility at all times.

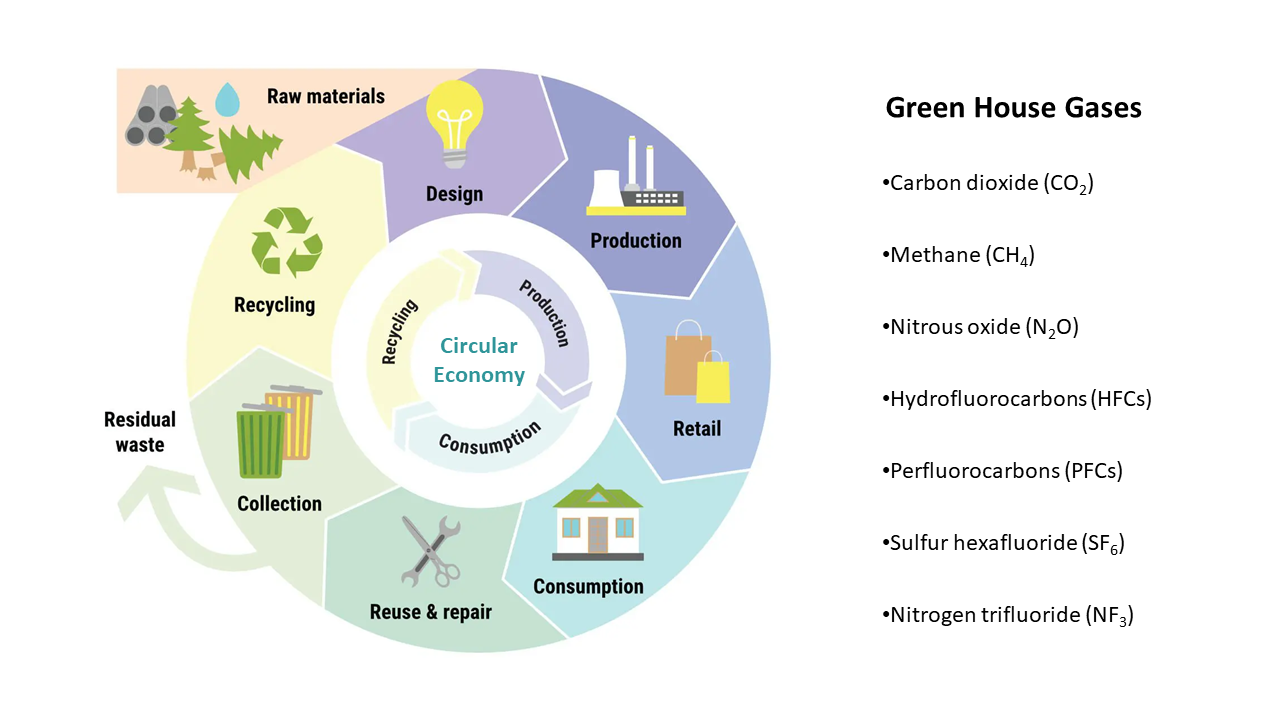

However, the textile and apparel industry is a major contributor to GHG (Green House Gas) emissions globally. According to a report by the Ellen MacArthur Foundation, the apparel and footwear industries combined account for 8% of global greenhouse gas emissions. Within the apparel industry, the production phase is responsible for the majority of emissions, accounting for 67% of total emissions. This includes the energy-intensive processes involved in dyeing, printing, and finishing fabrics, as well as the production of synthetic fibers.

In Bangladesh, the apparel industry is one of the largest contributors to the country’s economy, accounting for 84% of its total exports and providing employment for over four million people (Bangladesh Garment Manufacturers and Exporters Association, 2020). However, it is also one of the major contributors to environmental pollution, with a significant impact on greenhouse gas emissions. According to a study conducted by the Bangladesh Garment Manufacturers and Exporters Association (BGMEA) in 2019, the textile and apparel industry in Bangladesh contributes to around 4.6% of the country’s total greenhouse gas emissions (BGMEA, 2019).

To be mentioned, there is limited data available regarding the specific impact of circular economy practices on GHG emissions in the Bangladesh apparel industry. As circular practices are relatively new in the industry, more research is needed to fully understand their potential impact on GHG emissions. However, most of the greenhouse gas emissions from the textile and apparel industry come from energy consumption during production processes, such as spinning, weaving, dyeing, printing, and finishing. In addition, the industry is also responsible for emissions resulting from the transportation of raw materials and finished products.

Circular Economy practices have the potential to significantly reduce the GHG emissions associated with the apparel industry in Bangladesh. By promoting resource efficiency, reducing waste and pollution, and shifting towards renewable energy sources, Circular Economy practices can help to mitigate the environmental impacts of apparel production. For example, using recycled materials in the production process can significantly reduce the carbon footprint of clothing items, as it requires less energy to produce recycled materials than virgin materials.

However, the potential benefits in terms of reduced GHG emissions and a more sustainable industry are significant. Circular Economy practices in Bangladesh’s Apparel Industry have the potential to lead to a greener and more sustainable industry. The shift towards Circular Economy practices has already begun in Bangladesh’s apparel industry, with some companies adopting sustainable production methods and incorporating recycling and waste reduction measures into their operations. One key area where Circular Economy practices are making an impact is in reducing the environmental impact of textile production. Traditional textile production methods are known to have a significant carbon footprint due to the energy and water required, as well as the chemicals used in dyeing and finishing. By adopting Circular Economy practices, such as using recycled materials, reducing water and energy usage, and implementing closed-loop production systems, the industry can significantly reduce its carbon emissions.

Moreover, by adopting Circular Economy practices, Bangladesh’s apparel industry could improve its international competitiveness. Consumers and buyers are increasingly demanding sustainable and ethically-produced products, and companies that fail to meet these expectations risk losing market share. By adopting Circular Economy practices, companies in Bangladesh’s apparel industry can demonstrate their commitment to sustainability and gain a competitive edge in the global market.

Several initiatives have already been launched in Bangladesh to promote Circular Economy practices in the apparel industry. For example, the Bangladesh Garment Manufacturers and Exporters Association (BGMEA) has launched a “Circular Fashion Partnership” project in collaboration with the International Labour Organization (ILO) and the United Nations Environment Programme (UNEP), which aims to promote sustainable production and consumption in the industry.

While there is still a long way to go to fully integrate Circular Economy practices into Bangladesh’s Apparel Industry, the potential benefits for reducing GHG emissions are clear. As the industry continues to grow and faces increasing pressure to address its environmental impact, it is likely that Circular Economy practices will play an increasingly important role in promoting sustainability and mitigating the industry’s contribution to global GHG emissions.

There are several measures that could be taken to reduce GHG emissions in the Bangladesh apparel industry, including:

- Energy efficiency: One of the most effective ways to reduce GHG emissions is to improve energy efficiency. This can be achieved through a range of measures, including the use of more efficient machinery and equipment, the implementation of energy management systems, and the adoption of renewable energy sources.

- Sustainable materials: The use of sustainable materials in textile and garment production can significantly reduce GHG emissions. For example, the use of organic cotton, recycled polyester, and other sustainable materials can help to reduce the carbon footprint of textile and garment production.

- Circular economy practices: Adopting circular economy practices such as recycling, reusing, and repurposing can help to reduce the GHG emissions associated with textile and garment production. By keeping materials in use for as long as possible, circular economy practices can help to reduce the demand for new materials and the associated emissions.

- Improved supply chain management: Reducing GHG emissions in the apparel industry also requires improvements in supply chain management. This can include measures such as reducing transportation distances, optimizing shipping routes, and using low-emission transport options.

- Consumer behavior: Finally, consumer behavior also plays an important role in reducing GHG emissions in the apparel industry. Encouraging consumers to buy sustainable and eco-friendly products, and to recycle and dispose of their clothing responsibly, can help to reduce the environmental impact of the apparel industry.

Implementing these measures will require collaboration and cooperation among all stakeholders in the apparel industry, including manufacturers, suppliers, retailers, consumers, and policymakers.

There are also challenges to implementing Circular Economy practices in Bangladesh’s apparel industry, such as lack of awareness, limited technical expertise, and inadequate infrastructure. These challenges must be addressed through targeted investments in education, training, and infrastructure development to support the transition to a Circular Economy.

The adoption of Circular Economy practices in Bangladesh’s apparel industry has the potential to lead to a greener and more sustainable industry, reduce the industry’s carbon footprint, improve resource efficiency, and increase international competitiveness. With the right policies, investments, and support, Bangladesh can position itself as a leader in sustainable textile production and contribute to a more sustainable global apparel industry.

Author:

Dr. Md Ekram Hossain

Research Faculty (Assistant Professor), Hohai University, China

Email: mdekram_hossain@hhu.edu.cn