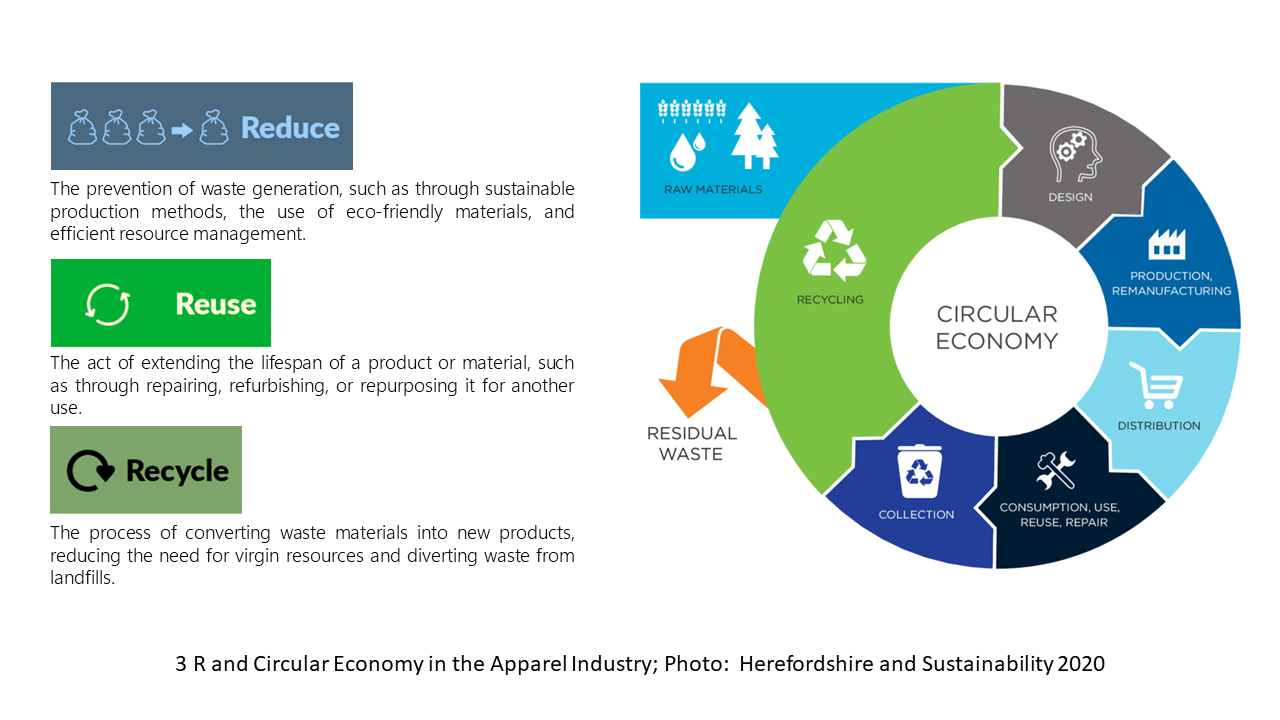

The adoption of the 3Rs principle (Reduce, Reuse, and Recycle) and the implementation of circular economy practices have the potential to transform Bangladesh’s apparel industry by increasing its sustainability and competitiveness. The apparel industry in Bangladesh is one of the largest export-oriented industries, contributing significantly to the country’s GDP and employing a large number of people. However, the industry is also responsible for significant environmental degradation and pollution, as well as social and labor issues. The adoption of the 3Rs principle in the apparel industry can contribute to reducing waste and resource consumption. The reduction of waste and resource consumption can have significant economic and environmental benefits. For example, reducing waste can reduce production costs and increase resource efficiency. This, in turn, can increase the competitiveness of the industry, as companies can produce products at a lower cost while minimizing their environmental impact. The reuse and recycling of materials also have significant economic and environmental benefits. Recycling materials can reduce the need for virgin materials, saving energy and reducing greenhouse gas emissions. Reusing materials can also reduce waste and save resources. By adopting circular economy practices, the industry can create a closed-loop system where waste is minimized, resources are conserved, and products are reused and recycled.

The prospect of the Bangladesh apparel industry adopting circular economy practices and the 3Rs principle is promising. The government of Bangladesh has initiated several programs and policies to promote sustainable production and consumption. For example, the government has established the Sustainable Apparel Forum, a platform for stakeholders to discuss and promote sustainability in the apparel industry. The Bangladesh Garment Manufacturers and Exporters Association (BGMEA) has also taken initiatives to promote sustainable production practices in the industry. The BGMEA has launched a Sustainability Compliance Academy, which provides training and education on sustainable production practices to industry professionals. Many international buyers are increasingly demanding sustainable production practices from their suppliers. Major brands such as H&M, Adidas, and Nike have committed to sustainable production and sourcing practices, and they require their suppliers to comply with strict environmental and social standards.

According to a study by the International Finance Corporation (IFC), the implementation of 3Rs (reduce, reuse, recycle) and circular economy practices in the Bangladesh apparel industry has the potential to reduce waste generation by up to 80%, leading to significant environmental benefits. Additionally, the study found that the implementation of these practices could lead to potential cost savings of up to 22% for manufacturers through reduced material usage and waste management costs. One example of a successful circular economy initiative in the Bangladesh apparel industry is the “closed-loop production” model adopted by some factories. In this model, waste materials from the production process are collected and reused to produce new garments or other products, thereby reducing waste generation and material consumption.

According to a report by the Bangladesh Garment Manufacturers and Exporters Association (BGMEA), the adoption of circular economy practices in the apparel industry could also enhance the competitiveness of the industry by reducing production costs and improving the sustainability of the supply chain. The report suggests that circular economy practices can create new business opportunities, increase efficiency, and generate economic value. There are also challenges to the implementation of circular economy practices in the Bangladesh apparel industry. One major challenge is the lack of awareness and understanding of circular economy principles among manufacturers and stakeholders in the supply chain. Additionally, there may be a lack of access to technologies and infrastructure necessary for circular economy practices, and cost considerations may also be a barrier to adoption.

There are challenges to implementing circular economy practices in the Bangladesh apparel industry, the potential benefits in terms of reducing waste, improving sustainability, and enhancing competitiveness suggest that it is a promising prospect for the industry. There are both opportunities and challenges in implementing the 3Rs and circular economy practices in Bangladesh’s apparel industry.

Opportunities:

- Increased market demand: Consumers around the world are becoming more conscious of sustainable practices and are demanding eco-friendly products. The implementation of the 3Rs and circular economy practices can increase the market demand for Bangladesh’s apparel industry products.

- Cost savings: The implementation of the 3Rs and circular economy practices can result in cost savings for the industry. The reduction in waste generation, reuse of resources, and recycling can result in reduced raw materials and production costs.

- Improved brand reputation: The adoption of sustainable practices can improve the brand reputation of Bangladesh’s apparel industry. This can lead to increased sales and customer loyalty.

- Access to new markets: Implementing 3Rs and circular economy practices can make Bangladesh’s apparel industry more attractive to eco-conscious consumers and retailers in developed markets, which can create new business opportunities and boost exports.

- Innovation: Adopting circular economy practices can lead to new and innovative product designs, as well as new business models such as product-as-a-service or leasing.

- Increased competitiveness: Implementing circular economy practices can help the Bangladesh apparel industry remain competitive with other low-cost garment manufacturing countries in the region by improving efficiency, quality, and sustainability.

- Resource security: By reducing reliance on virgin raw materials, implementing 3Rs and circular economy practices can help ensure a more secure and stable supply chain of materials for the industry.

- Increased consumer demand for sustainable and ethical fashion products, leading to the potential for higher sales and brand reputation for companies that adopt circular economy practices.

- Opportunities for new business models, such as clothing rental services or reselling used garments, can create new revenue streams for companies.

- Improved resource efficiency, potentially reducing costs and increasing profitability for companies.

- Enhanced collaboration between stakeholders in the apparel industry, including suppliers, manufacturers, and retailers, can lead to knowledge sharing, innovation, and improved sustainability practices.

Challenges:

- Lack of awareness: There is a lack of awareness among stakeholders regarding the benefits of the 3Rs and circular economy practices. This can make it difficult to convince industry players to adopt these practices.

- Infrastructure: Bangladesh’s apparel industry lacks the necessary infrastructure for implementing 3Rs and circular economy practices. This includes recycling facilities, waste collection and segregation facilities, and other supporting infrastructure.

- Regulatory framework: The regulatory framework in Bangladesh may not be conducive to the adoption of the 3Rs and circular economy practices. There may be a need for regulatory changes to encourage the implementation of these practices.

- Technology: The implementation of the 3Rs and circular economy practices requires the use of advanced technology. The lack of access to such technology can be a barrier to the adoption of these practices in Bangladesh’s apparel industry.

- Cost: While the implementation of the 3Rs and circular economy practices can result in cost savings, there may be initial investment costs that can be a barrier to adoption for some industry players.

- Limited awareness and understanding: There is currently limited awareness and understanding of the 3Rs and circular economy practices within the Bangladesh apparel industry, particularly among small and medium-sized enterprises (SMEs), which make up the majority of the industry.

- Lack of investment: Implementing 3Rs and circular economy practices often requires significant investment in new technology and processes, which may be a challenge for SMEs with limited financial resources.

- Regulatory and policy barriers: Existing regulations and policies may not support the adoption of circular economy practices in the industry, and may even hinder progress.

- Limited infrastructure: There is limited infrastructure in place for recycling and waste management in Bangladesh, which can make it difficult to implement circular economy practices.

- Cultural attitudes: Cultural attitudes towards waste management and recycling may need to shift in order for the 3Rs and circular economy practices to be successful in the Bangladesh apparel industry.

- High initial investment costs for companies to adopt circular economy practices, such as implementing closed-loop production systems or developing new business models.

- Limited awareness and understanding of circular economy principles among stakeholders in the apparel industry, including consumers, suppliers, and manufacturers.

- Complex supply chains with multiple stakeholders can make it difficult to trace the origin of materials and track the flow of products throughout their lifecycle.

- Limited availability of sustainable materials and technologies, can hinder companies’ ability to adopt circular economy practices.

In conclusion, the 3Rs (reduce, reuse, recycle) and the circular economy hold great prospects for the sustainable development of Bangladesh’s apparel industry. Implementing these practices can result in significant economic, environmental, and social benefits, such as reduced production costs, minimized waste generation, and improved working conditions. To fully realize the potential of the 3Rs and the circular economy, a collaborative effort from all stakeholders, including the government, industry players, and civil society, is essential. With the right policies, incentives, and investments, Bangladesh’s apparel industry can transition towards a more sustainable and circular business model while ensuring its competitiveness in the global market.

Author:

Dr. Md Ekram Hossain

Research Faculty (Assistant Professor), Hohai University, China

Email: mdekram_hossain@hhu.edu.cn