Bangladesh’s apparel industry is a vital contributor to the country’s economy, accounting for over 80% of the country’s total exports and providing employment for millions of people, particularly women. The industry has experienced significant growth over the past few decades, due in part to low labor costs and government support. However, the industry has also faced challenges, such as poor working conditions, low wages, and concerns about environmental sustainability.

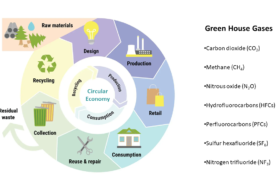

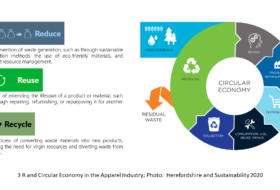

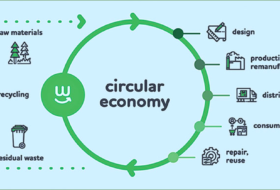

To address these challenges, many stakeholders in the industry have been exploring the adoption of circular economy principles and practices, which have the potential to improve environmental sustainability, enhance economic growth, and promote social equity. The shift towards Circular Economy practices has already begun in Bangladesh’s apparel industry, with some companies adopting sustainable production methods and incorporating recycling and waste reduction measures into their operations.

One key area where Circular Economy practices are making an impact is in reducing the environmental impact of textile production. Traditional textile production methods are known to have a significant carbon footprint due to the energy and water required, as well as the chemicals used in dyeing and finishing. By adopting Circular Economy practices, such as using recycled materials, reducing water and energy usage, and implementing closed-loop production systems, the industry can significantly reduce its carbon emissions.

To reduce the carbon footprint of textile production, Circular Economy practices can also reduce waste and improve resource efficiency. This can lead to cost savings for businesses, as well as reduced environmental impact. For example, by implementing closed-loop systems, where waste materials are reused or recycled instead of being sent to landfill, businesses can reduce their waste disposal costs and reduce the need for new raw materials.

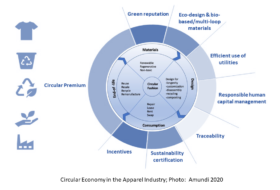

Moreover, by adopting Circular Economy practices, Bangladesh’s apparel industry could improve its international competitiveness. Consumers and buyers are increasingly demanding sustainable and ethically-produced products, and companies that fail to meet these expectations risk losing market share. By adopting Circular Economy practices, companies in Bangladesh’s apparel industry can demonstrate their commitment to sustainability and gain a competitive edge in the global market.

Bangladesh’s apparel industry has made progress toward adopting green industry practices, but there is still a long way to go. Many garment factories in the country still rely heavily on fossil fuels and use outdated technology, resulting in high energy consumption and greenhouse gas emissions. However, there are some initiatives and efforts underway to promote green industry practices in the sector.

According to a report by the United Nations Industrial Development Organization (UNIDO), a pilot project was launched in Bangladesh in 2019 to promote green industrial practices in the textile and apparel sector. The project aimed to demonstrate the feasibility of implementing sustainable production methods and technologies in the industry. As part of the project, six garment factories in Bangladesh were selected to receive technical assistance and training to adopt eco-friendly production practices. The factories were provided with energy audits and recommendations for reducing energy consumption and improving energy efficiency. The project also promoted the use of renewable energy sources, such as solar power, to reduce dependence on fossil fuels.

Several green initiatives have been taken by some of the leading apparel companies in Bangladesh. For instance, the apparel manufacturer and exporter, DBL Group, has set up a green factory that runs on 100% renewable energy. The factory, which was inaugurated in 2019, has installed 5 MW solar panels on its rooftop, making it the largest rooftop solar power plant in Bangladesh. The factory also uses energy-efficient machinery and technologies to reduce energy consumption and greenhouse gas emissions.

Despite these efforts, a significant proportion of Bangladesh’s apparel industry still lacks the resources and capacity to adopt green industry practices. Therefore, more support and incentives are needed to encourage the industry to shift towards sustainable production methods and technologies. The government can play a crucial role in this regard by providing financial and technical support to small and medium-sized enterprises in the industry. The government can also offer tax incentives and subsidies to companies that invest in renewable energy and adopt eco-friendly production methods.

According to a study by the International Finance Corporation (IFC) published in 2020, the Bangladesh Ready-Made Garments (RMG) industry has made significant progress in adopting sustainable and green practices. The study surveyed 77 factories, representing approximately 4% of the country’s total export-oriented RMG factories. Here are some key findings from the study:

- Energy efficiency: The study found that the surveyed factories have made considerable progress in improving their energy efficiency. On average, the factories have reduced their energy consumption by 8.5% through measures such as installing energy-efficient lighting, optimizing machine operations, and improving insulation.

- Water conservation: The surveyed factories have also taken measures to reduce water consumption. On average, the factories have reduced their water consumption by 6.5%. Measures taken include recycling and reusing water, optimizing washing processes, and using low-flow faucets and toilets.

- Waste management: The factories have implemented measures to reduce waste and improve waste management. On average, the factories have reduced their waste generation by 6.2%. The factories have also implemented recycling and reuse programs for materials such as paper, plastic, and metal.

- Green certifications: The study found that 61% of the surveyed factories have obtained at least one green certification, such as LEED or GOTS. This indicates a growing interest among the factories in adopting sustainable and green practices.

It is predicted that the adoption of Circular Economy practices could accelerate the shift towards green industry in the Bangladesh apparel industry. By adopting circular practices, such as reducing waste and implementing closed-loop systems, the industry can reduce its environmental impact while also improving its economic performance. As the industry continues to grow and evolve, it is expected that sustainable and green practices will become increasingly important for its long-term viability.

In recent years, the government of Bangladesh has taken various initiatives to promote green industry practices in the apparel sector. The country has set a target of reducing greenhouse gas emissions by 5% by 2030, and the apparel industry is expected to play a significant role in achieving this target.

Several leading apparel brands in Bangladesh have committed to incorporating sustainable and circular practices in their operations. The Bangladesh Garment Manufacturers and Exporters Association (BGMEA) has also launched a number of initiatives to promote green industry practices in the apparel sector.

One of the most significant initiatives is the “Green Factory” certification program, which is aimed at promoting environmentally sustainable practices in the country’s apparel factories. As of January 2021, more than 100 apparel factories in Bangladesh have received this certification. In addition, the BGMEA has also launched a number of other initiatives, such as the “Zero Discharge of Hazardous Chemicals” program, which aims to eliminate the use of hazardous chemicals in the country’s apparel factories.

The economic contribution of green industry practices in the Bangladesh apparel industry can be significant. According to a study by the International Finance Corporation (IFC), adopting sustainable practices in the apparel sector in Bangladesh can lead to cost savings of up to 15% and increased revenue of up to 9%. This can result in a net financial benefit of up to $8.2 billion for the industry.

Adopting green industry practices such as a circular economy in Bangladesh’s apparel industry can improve the competitiveness of the industry. Here are some ways it can contribute to composite the industry:

- Cost savings: By implementing circular economy practices, the industry can reduce its raw material consumption and waste, leading to cost savings. This can make the industry more competitive by reducing production costs.

- Innovation: Adopting circular economy practices can promote innovation in the industry. For example, finding new ways to reuse and recycle waste materials can lead to new product development and competitive advantage.

- Improved reputation: The adoption of green industry practices can improve the industry’s reputation and brand image. Consumers are increasingly concerned about the environmental impact of the products they purchase, and companies that prioritize sustainability can gain a competitive edge in the market.

- Access to new markets: Some markets and buyers may have sustainability requirements for their suppliers. By adopting circular economy practices, Bangladesh’s apparel industry can gain access to these markets and buyers.

According to a study by the International Labor Organization (ILO), the adoption of sustainable practices in the textile and garment industry in Bangladesh can have positive impacts on the country’s economy, including the creation of new jobs and increased competitiveness in the global market. Another study by the Bangladesh Garment Manufacturers and Exporters Association (BGMEA) found that 80% of buyers are willing to pay a premium for sustainable products, highlighting the potential economic benefits of adopting green industry practices.

A report by the International Finance Corporation (IFC) found that by implementing resource efficiency measures, such as water and energy conservation, Bangladesh’s apparel industry can save up to $1.2 billion annually. The same report also found that by adopting circular economy practices, such as waste reduction and recycling, the industry can reduce production costs by up to 15%. In addition, a survey conducted by the BGMEA found that nearly 70% of apparel manufacturers in Bangladesh have adopted green industry practices, such as water conservation and renewable energy use, indicating a growing trend toward sustainability in the industry.

A study conducted by the Bangladesh Centre for Advanced Studies (BCAS) estimated that the total economic cost of environmental degradation in Bangladesh was approximately 4.3% of the country’s GDP in 2009. This cost includes both direct and indirect impacts of environmental damage, such as health impacts, loss of productivity, and increased expenditure on environmental remediation.

By implementing green industry practices, the environmental damage and costs associated with the apparel industry could be reduced, leading to a positive impact on the country’s GDP. This is because companies would be able to operate more efficiently and sustainably, reducing their costs and improving their profitability. Additionally, a more sustainable and environmentally conscious image of the industry could attract more customers and investors, leading to further economic growth.

The adoption of green industry practices could also lead to job creation and increased incomes. A report by the International Labour Organization (ILO) found that transitioning to a green economy could generate around 1.2 million new jobs in Bangladesh by 2023, primarily in the areas of renewable energy and sustainable agriculture. This could help to reduce poverty and improve living standards in the country. Green industry practices in the apparel industry can improve the competitiveness of the industry by creating more sustainable and resilient production processes, reducing costs, increasing efficiency, and attracting environmentally conscious consumers.

Green industry practices can also attract foreign investment and create new opportunities for export markets. Bangladesh’s apparel industry is heavily dependent on exports, and the adoption of sustainable practices can help attract more international buyers who are looking for environmentally friendly products. Green industry practices can improve the overall image of the industry, which has faced criticism in the past for poor working conditions, low wages, and environmental damage. By adopting sustainable practices, the industry can improve its reputation and become more attractive to consumers, investors, and international buyers.

However, the implementation of green industry practices is not without its challenges, including the need for significant upfront investments in technology and infrastructure, changes in consumer behavior, and potential disruptions to existing supply chains. It requires the commitment of stakeholders across the industry, including manufacturers, suppliers, retailers, and consumers, to drive sustainable change. Implementing green industry practices may require initial investments and changes in the production process, which could lead to increased costs in the short term. However, in the long run, green industry practices have the potential to reduce costs through resource efficiency, waste reduction, and energy savings.

Buyers are becoming increasingly interested in sustainability and green practices, including in the apparel industry. They are putting pressure on suppliers to adopt sustainable and circular economy practices, including reducing waste and greenhouse gas emissions, using renewable energy sources, and ensuring ethical and safe working conditions for workers.

Many large retailers and brands have established their own sustainability targets and are requiring their suppliers to meet them. For example, H&M has set a goal of becoming 100% circular and climate-positive by 2030 and has been working with its suppliers to improve their sustainability practices. Other brands, such as Adidas and Nike, have set similar targets and are working with their suppliers to achieve them.

There are several challenges to implementing green industry practices in the Bangladesh apparel industry, including:

- High initial investment costs: Implementing green industry practices often requires significant upfront investments in new equipment, processes, and technology. These costs can be prohibitive for many small and medium-sized enterprises (SMEs) in the apparel industry.

- Limited access to finance: Access to finance remains a significant challenge for SMEs in Bangladesh, and many banks and financial institutions may be hesitant to lend to businesses that are transitioning to green industry practices.

- Limited technical expertise: The adoption of green industry practices often requires technical expertise that may not be readily available in Bangladesh. This can lead to delays in implementation and additional costs associated with hiring outside consultants or experts.

- Limited awareness and capacity building: Many apparel industry stakeholders in Bangladesh may not be aware of the benefits of green industry practices, and there may be limited capacity-building programs available to support the transition.

- Lack of supportive policies and regulations: There may be limited policies and regulations in place to support the adoption of green industry practices in Bangladesh’s apparel industry. Without supportive policies and regulations, businesses may be less motivated to invest in new practices.

While there are challenges to implementing green industry practices in Bangladesh’s apparel industry, the potential benefits in terms of environmental sustainability, economic growth, and social development make it an important area for continued focus and investment.

In the context of Bangladesh’s apparel industry, the adoption of green industry practices is likely to be viewed positively by many buyers. This is because the industry has been plagued by a number of environmental and social issues in recent years, including concerns about water pollution, worker safety, and labor rights. By adopting more sustainable practices, companies in the industry can demonstrate a commitment to addressing these issues, which may help to improve their reputation among buyers and consumers.

Smaller suppliers in Bangladesh may face challenges in implementing sustainable practices due to a lack of resources and financial constraints. In addition, buyers may still prioritize cost over sustainability, which can make it difficult for suppliers to justify the investment in green industry practices. It is important for both suppliers and buyers to work together to overcome these challenges and promote sustainable practices in the apparel industry.

However, there is evidence to suggest that sustainability can be a key driver of competitiveness in the apparel industry. A study by the Boston Consulting Group found that companies that invest in sustainability are more likely to achieve above-average growth and profitability. This suggests that companies that adopt green industry practices may be better positioned to compete in the global marketplace over the long term. As consumer demand for sustainable products increases, companies that adopt green industry practices may be able to access new markets and increase their competitiveness. This could ultimately lead to increased revenues and economic growth for the country. While there may be some initial costs associated with implementing green industry practices, it can ultimately be cost-effective for the Bangladeshi apparel industry in the long run.

Author:

Dr. Md Ekram Hossain

Research Faculty (Assistant Professor), Hohai University, China

Email: mdekram_hossain@hhu.edu.cn